In-clinic cGMP Pharmacies

The agility you need to small-batch manufacture and formulate with accuracy.

Quality, safety, agility and speed. We get your early-phase studies started quickly, avoiding the costs and delays typically associated with drug product manufacture and formulation.

Quality and safety

Quality and safety come first at Fortrea. With on-site GMP Pharmacies at all four Fortrea dedicated CRUs, we support reliable, high-quality data and patient safety during phase 1 trials.

Timeline reduction

The agility to significantly reduce drug manufacture timelines for clinical trials allows sponsors to reduce study timelines and make adjustments to formulations based on trial results.

Grams of API. Not Kilograms.

On-site small batch manufacture avoids the high-cost and API wastage associated with using contract manufacturing organizations (CMOs). Our in-clinic cGMP Pharmacies require grams, not kilograms of API for extemporaneous preparation.

Seamlessly integrating manufacture and trial

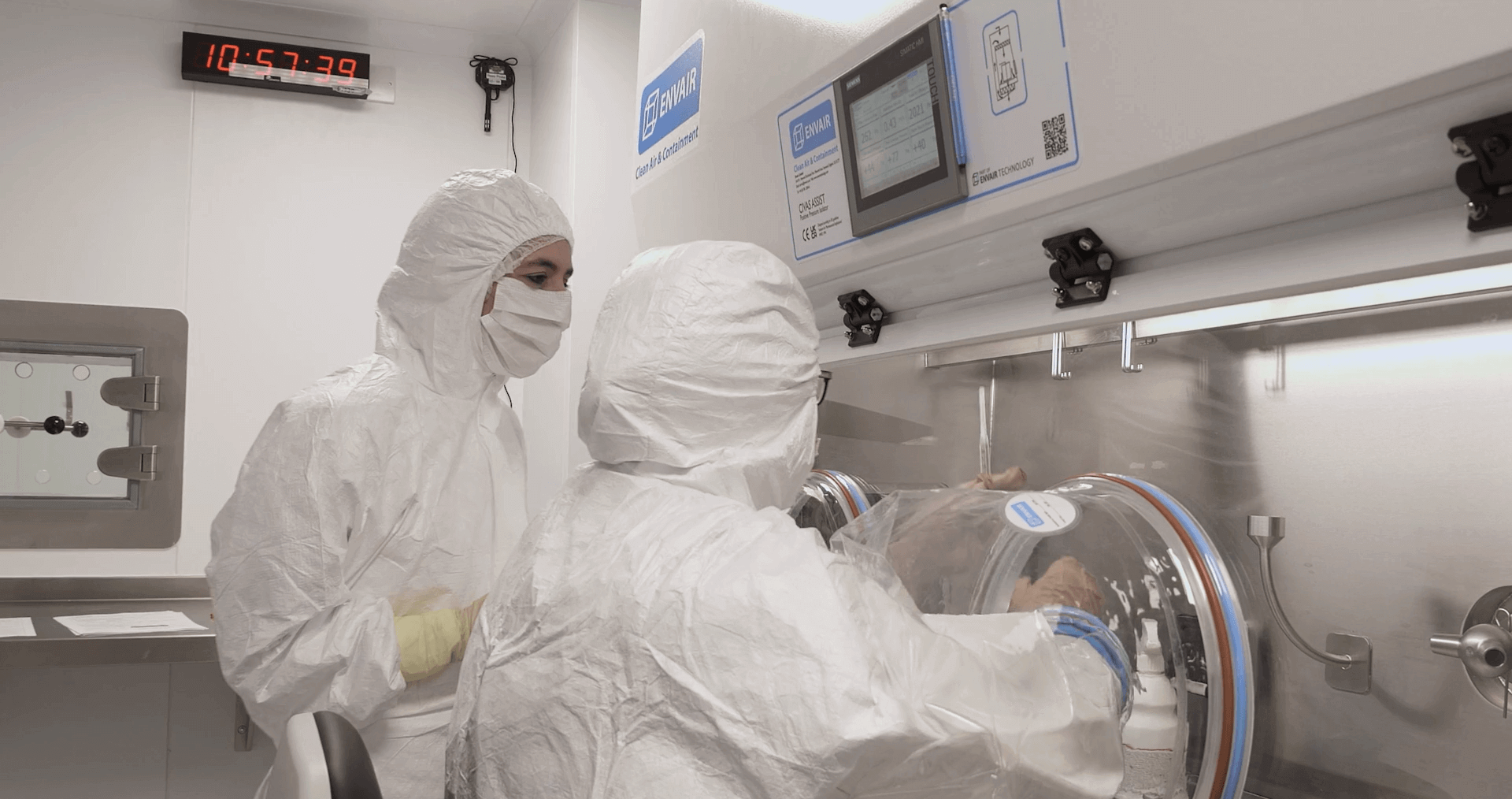

Fortrea is the only CRO to combine high-quality small-batch manufacturing and on-site formulation of drug product within all of its dedicated phase I Clinical Research Units (CRUs). We are uniquely positioned to offer developers agility, cost and time savings without compromising quality or safety.

Integrating cGMP manufacturing and clinical conduct at the same facility allows:

- Significantly reduced API cost by requiring minimal API, typically less than 500grams

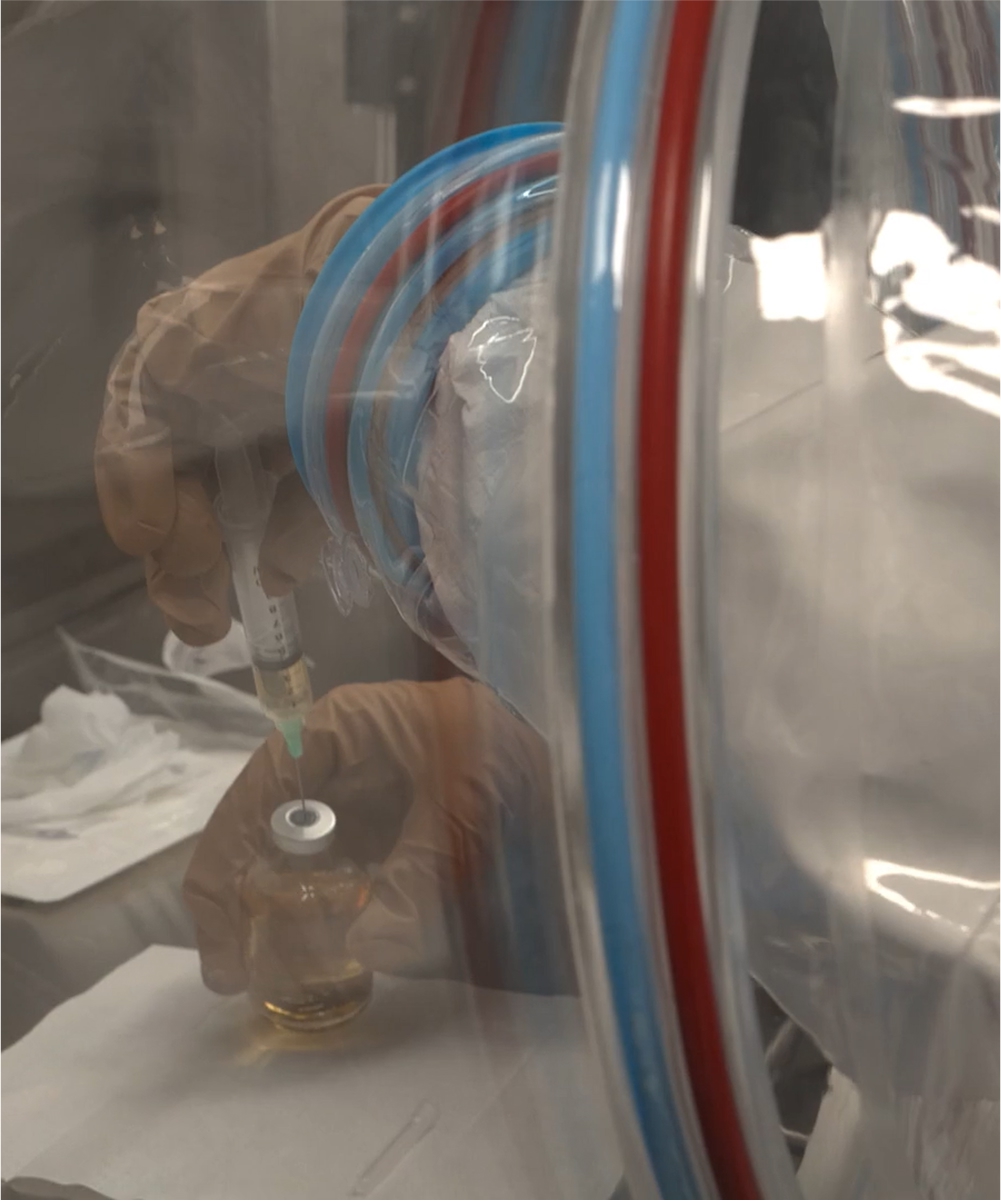

- Reduced drug product stability requirements, formulating and delivering direct to study participants

- Agility and control over drug product formulation

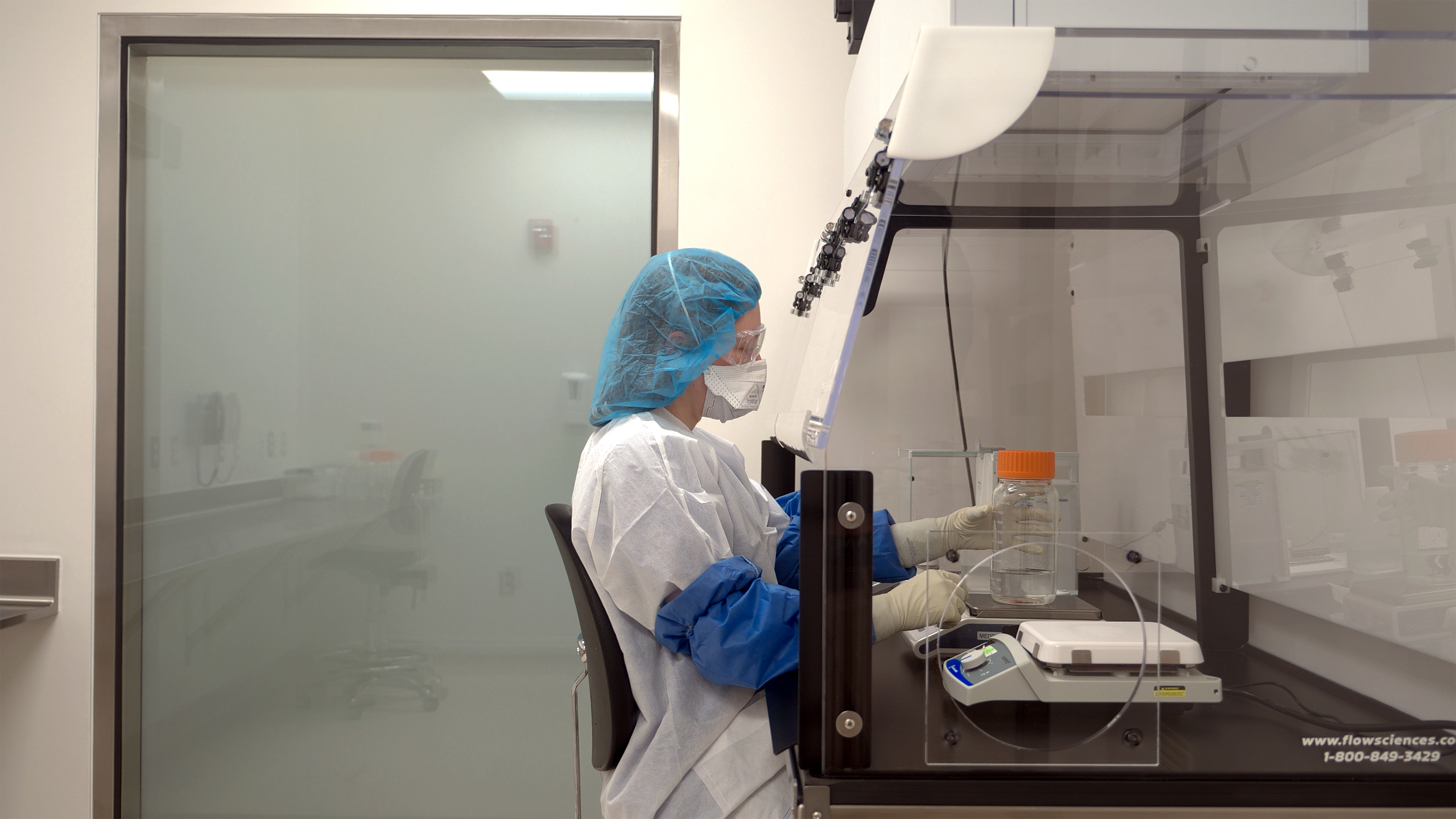

To achieve this, Fortrea has invested in the construction and certification of ISO 7 (Grade C) & ISO 8 (Grade D) clean rooms for sterile and non-sterile manufacturing in controlled environments, and in working enclosures that meet ISO 5 (Grade A) air quality standards for sterile manufacturing or assembly, with containment equipment including powder cabinets for non-sterile manufacture.

These facilities are equipped to handle high-potency and hazardous drugs, ensuring that we can meet the diverse needs of our clients, delivering various drug formulations including:

- Capsules (liquid & powder)

- Oral solutions and suspensions

- Injectable (sterile) solutions

- Radiolabeled formulations (for AME studies)

Quality, CMC control and agility

While traditional compounding pharmacies offer pharmacist oversight, the use of cGMP Pharmacies on-site at our CRUs offers a quality management system (QMS) ensuring quality specifications and complete process information control related to chemistry, manufacturing and controls (CMC) for use in later trial stages and investigational new drug (IND) amendments.

And without the need to utilize a CMO for small batch manufacture, Fortrea is able to offer agility and cost saving without sacrificing quality – the same quality as a CMO without the costs, waste and inflexibility.

Comparative benefits for Phase I drug manufacturing sources

First-in-human trials are, by their nature, explorative. By certificating cGMP Pharmacies in all 4 of our dedicated Clinical Research Units in the USA and UK, we offer developers significant cost savings, flexibility and choice to safely bring API to healthy volunteers and patients.

| Benefits overview | cGMP at CMO | cGMP at CRU | Non-cGMP |

| Quality | Oversight by QMS | Oversight by QMS | Oversight by Pharmacists |

| Time | Longest | Shorter | Shortest |

| Quantity | 200 - 300% excess API | 1 - 25% excess API | 1 - 25% excess API |

| Cost | $$$$ | $$ | $ |

| Risk | ↓ | ↔ | ↑↑ |